How to Assemble Jet Drill Press: Step-by-Step Guide for Beginners

Do you have a new, shiny jet drill press that you can’t wait to use, but are feeling a bit intimidated by the thought of assembling it? Don’t worry, we’ve got you covered! We’ll walk you through the steps to get your drill press fully assembled and ready to use in no time. Assembling any tool can be a bit overwhelming, especially if you’re new to it. But with a bit of patience and guidance, it can be a breeze.

The Jet drill press is known for its durability and accuracy, making it a fantastic investment for any DIY enthusiast or professional. From the moment you open the box, you’ll notice that the Jet drill press comes with a surprisingly small number of components. That’s because the majority of the machine is preassembled at the factory, meaning you’ll only need to attach a few key parts to have it up and running.

In this article, we’ll go through each step of assembling your Jet drill press, from unpacking to final adjustments. By the end, you’ll be confident and ready to put your drill press to the test on your next project. So, let’s get started!

Prepare your workspace

If you have just bought a new Jet drill press, then it’s important to prepare your workspace carefully before assembling it. First, ensure that you have enough space to unpack and assemble all the parts of the drill press. It’s recommended to have a large and flat surface, like a workbench or table, that is at least as big as the dimensions of the drill press.

Clear away any clutter or debris from the space, as this will make it easier to work and move around. Then, gather all the necessary tools you’ll need, including sockets, wrenches, and pliers, as well as a level and measuring tape. Follow the manufacturer’s instructions carefully and double-check each step as you go.

Don’t rush the process and take your time to ensure that the drill press is assembled correctly and safely. Once you have assembled the drill press, test it out to be sure it is working properly. With these steps, you’ll be on your way to assembling your Jet drill press and having a reliable tool in your workspace for years to come.

Clear the area and gather necessary tools

Preparing your workspace before attempting any task is essential to ensure efficiency and avoid any possible mishaps. The first step is to clear the area you’ll be working on. Remove any objects that could hinder your movement or distract your attention.

Once you’ve cleared the area, gather all the necessary tools and equipment you’ll need for the job. This saves time, increases productivity, and ensures you don’t waste time searching for the right tool when you could be working productively. The keyword “prepare workspace” is crucial for this section as it highlights the importance of organizing your work area before delving into the task at hand.

A clean workspace helps increase focus and prevents accidents from occurring. Remember, a little preparation goes a long way in ensuring success and avoiding setbacks in any project.

Attach the Base

When it comes to assembling a Jet drill press, attaching the base is one of the first steps. Begin by locating the base and the column. Insert the column into the center hole of the base and tighten the bolts securely.

Do not over-tighten the bolts, as this can cause damage to the base. Next, locate the four leveling screws located at the corners of the base. Adjust each screw until the base sits level on the ground and there are no wobbles.

This is important for the stability of the drill press when in use. Once the base is level, attach the motor to the column using the provided hardware. Make sure the motor is securely attached and is facing the correct direction according to the instructions.

With the base attached, the Jet drill press is now ready for the next steps in the assembly process. Follow the instructions carefully to ensure a safe and accurate installation.

Assemble the base and attach the column to it

Attaching the base to the column of a piece of furniture may seem like a daunting task, but it can be easily accomplished with a few simple steps. First, make sure that the base is aligned with the bottom of the column, ensuring that it is centered and level. Once you have determined the correct placement, attach the base to the column using screws or bolts.

Make sure to use appropriate hardware that is strong enough to hold the weight of the furniture. It is important to ensure that the screws are tightened securely to avoid wobbling or instability. A tip to ensure that the base stays attached correctly is to add a small amount of wood glue or epoxy to the screw holes before inserting the screws.

This will create a strong, long-lasting bond between the base and the column. With these simple steps, you can confidently attach the base to the column of your furniture and enjoy a stable and sturdy piece of furniture for years to come.

Install the Table

If you’ve just bought a Jet drill press and don’t know where to start when it comes to assembly, don’t worry. In this tutorial, we’ll show you how to install the table. The table is an essential part of the drill press, providing a stable surface for your workpiece.

First, you’ll need to locate the table and the two bolts that come with it. Place the table face down on a flat surface and position the bolts in the two holes on the underside of the table. Slide the bolts through the holes and secure them with the two nuts that were supplied.

Tighten the nuts with a wrench until they are snug, taking care not to over-tighten. Once the nuts are tightened, flip the table over and attach it to the drill press. The table will typically slide onto a horizontal rod that is attached to the drill press.

Once it’s in place, tighten the set screw to secure the table. Congratulations! Your Jet drill press is now ready to use.

Attach the table to the column and make adjustments

Now that you have assembled the table, it’s time to attach it to the column. The first step is to locate the screw holes on the table. These holes will align with the holes on the column.

Use screws and a screwdriver to attach the table to the column. Be sure to tighten the screws securely to ensure that the table is stable and won’t wobble. Once the table is attached, check for any unevenness or wobbling.

Adjust the table by gently tapping the legs with a wooden mallet or by adjusting the screws for a proper fit. It’s important to make sure the table is level to prevent any items from sliding or falling off. With the table securely attached to the column and properly adjusted, you can now enjoy your new piece of furniture.

Mount the Motor

We’re now at the point in our assembly process where we need to mount the motor. It might seem intimidating at first, but it’s actually a pretty straightforward process. First, you’ll want to take a look at the instructions that come with your jet drill press to make sure you have all the necessary parts and tools.

Once you’ve confirmed that, you can begin by attaching the motor mount to the base of the drill press. Make sure you use the appropriate screws and bolts for this step. Next, attach the motor bracket to the motor itself, using the screws that came with the kit.

Once that’s done, you can slide the motor and bracket assembly onto the mount you attached to the base earlier. Secure it in place using the bolts and nuts provided. Voila! Your motor is now mounted and ready to go.

With this done, we’re one step closer to having a fully functional jet drill press.

Attach the motor to the column and connect the wires

To mount the motor for your project, you’ll need to attach it to the column and connect the wires properly. Start by securing the motor to the column with screws or bolts, depending on your setup. Be sure to consult the manufacturer’s instructions for proper alignment and torque specifications.

Once the motor is secure, you’ll need to connect the wires. Again, refer to the manufacturer’s instructions or wiring diagram to ensure that you connect the wires correctly. A wrong connection can damage the motor or cause it to malfunction, so it’s essential to double-check everything.

You may need to strip the wires and use connectors to make the proper connections. And don’t forget to use proper electrical safety precautions, such as turning off the power before working on the wiring. With a little patience and attention to detail, you can mount the motor and connect the wires with ease, completing an essential step in your project.

Attach the Chuck

If you’re wondering how to assemble a Jet drill press, the first step is to attach the chuck. This crucial component is responsible for holding the drill bits securely in place while allowing you to easily swap them out as needed. To get started, begin by removing the chuck from its packaging and inspecting it closely for any damage or defects.

Then, locate the spindle of your drill press and insert the chuck onto it, making sure it’s seated firmly and evenly. Next, use the chuck key provided to tighten the jaws of the chuck around the spindle, turning it clockwise until it’s snug. Be sure not to overtighten, as this could cause damage to the spindle or chuck.

Once you’ve attached the chuck, you’ll be ready to move on to the next step in assembling your Jet drill press.

Install and tighten the chuck onto the spindle

When it comes to getting your woodwork or metalwork project underway, attaching the chuck is an essential step that shouldn’t be overlooked. The chuck is the mechanism used to secure your drill bits or other attachments onto the spindle, ensuring that they rotate in tandem with the spindle itself. To install and tighten the chuck, start by making sure that the spindle is perfectly clean and free of any debris or buildup.

Next, open the chuck jaws by turning the chuck counterclockwise, and then insert your chosen drill bit or attachment into the hole in the center of the chuck. Finally, tighten the chuck jaws by turning the chuck clockwise, making sure that they grip the bit or attachment firmly and securely. It’s important to make sure that the chuck is tightened correctly so that your drill bit won’t slip or wobble during use.

With a properly secured chuck, you can drill and bore with confidence, knowing that your tools are functioning at peak performance.

Adjust for Speed and Depth

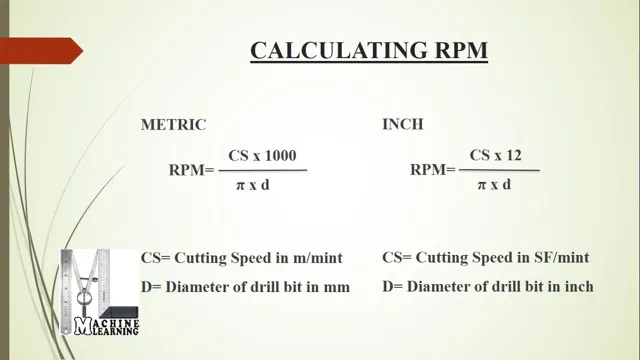

When assembling your jet drill press, one key factor to consider is adjusting for speed and depth. This is important because you want to ensure that you are not only drilling into the material of your choice, but also that you are doing so at the appropriate speed and depth. To adjust for speed, refer to your user manual and locate the speed chart.

Choose the appropriate speed based on the material you are working with. To adjust for depth, use the depth gauge and locking knob to set the depth of the drill bit. This will ensure that you are going to the desired depth without causing any unnecessary damage or creating a hole that is too shallow.

Remember, it’s important to take your time and be precise when adjusting for speed and depth to avoid damaging your project or your jet drill press.

Adjust the belt tension and depth stop

Adjusting the belt tension and depth stop is crucial when it comes to using power tools efficiently and accurately. With the right tension and depth stop, you’ll achieve consistent results every time you use the tool. To adjust the belt tension, you need to first loosen the nut holding the motor in place.

Move the motor until the belt has some slack, but not too much. Adjust the tension by pulling the motor away from the belt while tightening the nut. You want the belt to be tight, but not so tight that it puts unnecessary pressure on the motor.

When it comes to adjusting the depth stop, you need to consider the size of the material you’re working with and the type of cut you want to make. The depth stop should be adjusted to ensure that the tool doesn’t cut too deep or too shallow. It’s best to experiment with different settings until you find the one that works best for your project.

Overall, adjusting the belt tension and depth stop is an important step in achieving precise and accurate results with your power tools. Make sure to take your time and get it right before starting your next project.

Test and Use

If you’re a woodworker or metalworker, there’s no doubt that having a drill press is essential. The Jet drill press is an ideal tool for drilling accurate holes at the desired angle on any workpiece. However, assembling the tool can be a bit tricky if you don’t know what you’re doing.

Here’s how to assemble a Jet drill press in simple steps. First, unpack the components and check that all the parts are present. Then, start assembling the base and column by attaching the column to the base with bolts.

Next, install the head assembly by securing it to the column with bolts and then the table assembly. Lastly, attach the chuck and motor to finish assembling the drill press. Once you’ve assembled your Jet drill press, you’ll need to learn how to use it properly.

Begin by selecting the right drill bit and adjusting the depth to your desired measurement. Start by drilling a small pilot hole before drilling the final hole. Follow the manufacturer’s instructions for operating the press and use safety gear like protective glasses and earplugs when working.

With practice, you’ll master drilling precise holes every time with your Jet drill press.

Test the operation and use your new Jet Drill Press

Testing and using your new Jet Drill Press can be an exciting and fulfilling experience. Before you begin, it’s important to review the user manual and ensure you have all the necessary safety equipment, such as eye protection and proper clothing. Start by testing the drill press’s various settings, speeds, and adjustments.

You can experiment with different materials, thicknesses, and drill bit sizes to see how the machine handles each one. Practice making accurate, consistent, and efficient drill holes. Once you feel comfortable with the operation, you can move on to more advanced techniques, such as angled drilling and hole patterns.

Remember to always use caution and follow proper safety procedures throughout the process. With patience and practice, you can master the art of using your Jet Drill Press to create precise and professional-looking woodwork, metalwork, or any other project you set your mind to.

Conclusion

Assembling a Jet Drill Press may seem daunting at first, but with patience, precision, and a few helpful tips, you’ll have a powerhouse tool ready to tackle any project in no time. Remember to take your time, read the instructions carefully, and double-check your work as you go along. And if all else fails, just channel your inner Bob Ross and remember that there are no mistakes, only happy accidents.

Happy drilling!”

FAQs

What tools are required for assembling a Jet drill press?

The tools required for assembling a Jet drill press are Allen wrenches, wrenches, screwdrivers, pliers, and a rubber mallet.

Is it easy to assemble a Jet drill press?

Yes, the Jet drill press comes with an instruction manual that makes it easy to assemble. Follow the steps in the manual carefully.

Can I assemble the Jet drill press alone or do I need help?

It is recommended to assemble the Jet drill press with someone else’s help, as some parts of the press are heavy and difficult to hold alone.

How long does it take to assemble a Jet drill press?

The time taken to assemble a Jet drill press depends on the experience level of the person assembling it, but an average of 2-3 hours is required.

Are there any safety precautions to take while assembling a Jet drill press?

Yes, always wear safety glasses and gloves while assembling a Jet drill press. Also, make sure to read and follow the safety instructions in the manual.

What if I face difficulties while assembling the Jet drill press?

If you face difficulties while assembling the Jet drill press, you can refer to the troubleshooting guide in the manual or contact the customer support team of Jet for assistance.

Can I hire a professional to assemble the Jet drill press for me?

Yes, you can hire a professional to assemble the Jet drill press for you. However, it may cost you some extra money.